Enquire now

Enquire now

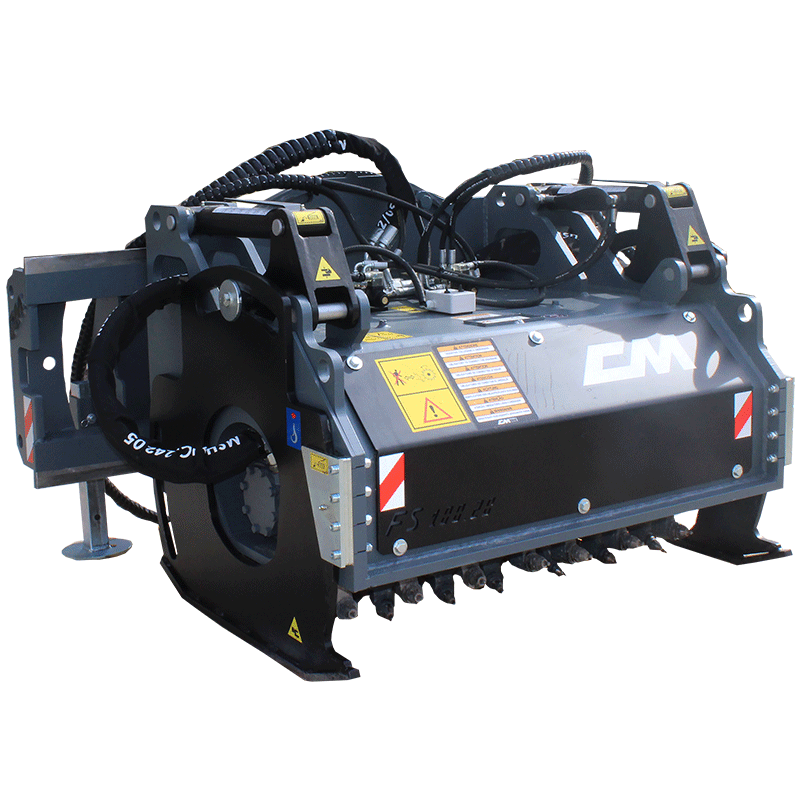

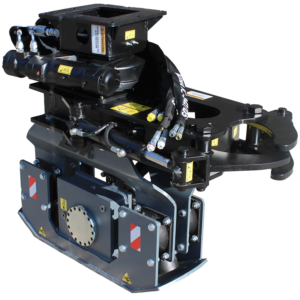

Road planer FS series

Highest productivity

Highest productivity

Self-levelling asphalt planer for skid-steer loaders, backhoe loaders and wheel loaders.

Self-levelling asphalt planer designed for application on skid-steer loaders, backhoe loaders and wheel loaders, capable of dismantling asphalt crusts, creating pre-defined sections, removing damaged surface layers or simplifying excavation operations.

- Constant milling depth

- Perfect finishing with side-by-side passes

- Stable and vibration-free

Self-levelling system

Thanks to the self-levelling system on the working surface, a constant milling depth is guaranteed under all conditions. The side slides of the road planer automatically align themselves to the

milling surface on which they rest, providing maximum stability.

Hydraulic side shift

Used in central or lateral position, to the right side for milling flush to the wall. (walls, sidewalks).

Independent depth adjustment.

The slides move independently of each other and precisely follow the surface to the right or left. The independent depth adjustment on RH and LH sides combined with the self-levelling system

achieves perfectly flat surfaces with sideby-side passes.

Cut and depth indicators

For constant and precise processing control.

Milling drum

Milling drum with different widths and sizes.

Tools for concrete

Hydraulic depth adjustment

Independent on both sides.

Watering kit with tank and 12/24 Volt pump

Supplied with 70 l tank and 12 or 24 V pump depending on the operating machine.

Hydraulic drum inclination

Customised attachment

Depending on the operating machine.

Plug&Play coupling

With the most important skid steer loaders on the market

Teeth for concrete or asphalt

Depending on the surface area to be treated

Watering kit

Standard watering kit provision

Bracket for skid steer loader

always as standard

Products

Products

Back to category

Back to category